It’s been a while since I posted an update, lots on the go including a move back to British Columbia. On the 20th of January I’m planning to run an armour tool workshop to help folks make some basic tools. The focus will be on making a sinking hammer, fluting stake and planishing stake. There is an older article on making a sinking hammer and I will link articles to the fluting stake and planishing stake once I have completed the workshop and have some appropriate pictures to finish the post.

Fluting Stake

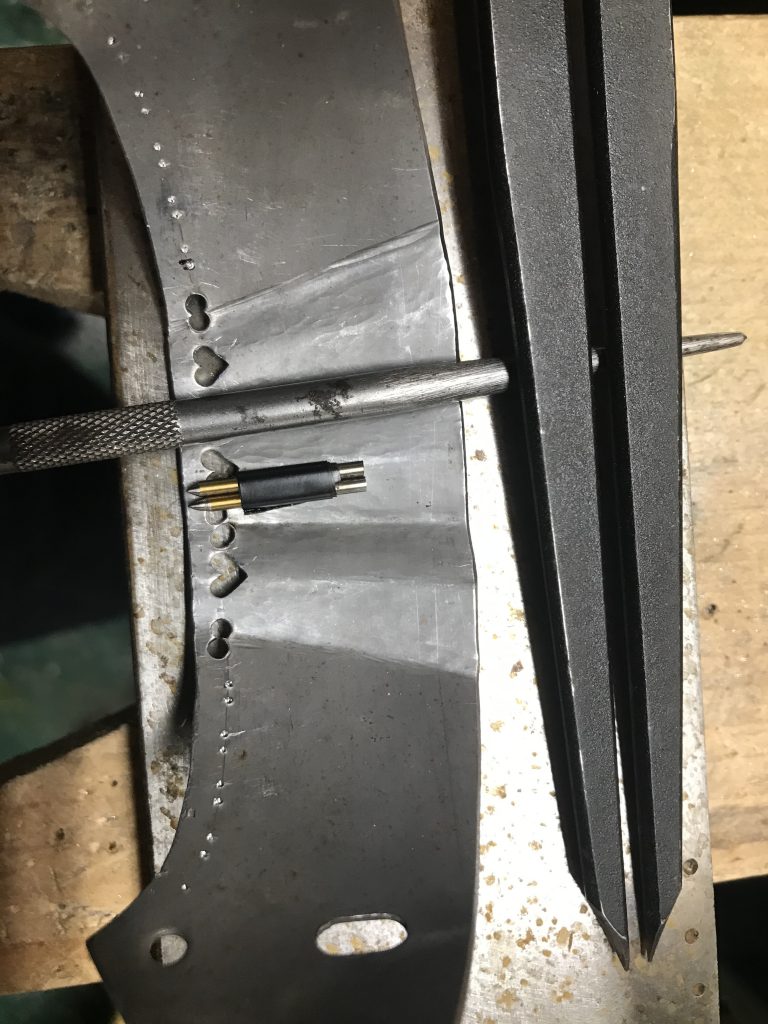

The fluting stake I use is a converted jackhammer bit originally used for removing asphalt, but any wide-bladed jackhammer bit will work. The above photo shows the 1/4 and edge profiles to give a better idea of the overall shape, and also shows the abuse to the mirror finish that this tool should have.

Cresting Stake

If there is time, I’d also like to make some cresting stakes, since these are invaluable for items such as gauntlets, helmets, greaves and breastplates to help form a clean crest line. These are made in a similar fashion to the planishing stakes with stock removal, but instead of removing material and making a dome, these are made with curved segments on each side intersecting to form a crest. Depending on the intent, this can be built (as this one is) with two intersecting sphere segments, suitable for elbows, knees or helmets, or it can be built with a straight profile (2 cylinder sections intersecting) much like back-to-back fluting stakes, which is appropriate for gauntlet sections.